ButtWeld Pipe Fittings from Balaji Industrial Corporation:

ButtWeld Pipe Fittings are used in connecting and creating pipe-work systems where they are welded into the system using circumferential butt welds. These pipe fittings are used in conjunction with ANSI pipe and flanges which can be supplied in the corresponding size ranges. Pipe Fittings are manufactured to dimensions and tolerances in accordance with ANSI B16.9 , ANSI B16.28, and MSS SP43.

Balaji Industrial Corporation, the leading buttweld fittings company, manufacture ButtWeld Pipe Fittings in the following forms and is also geared up to deliver as per specific customized requirements.

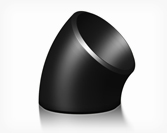

- Long radius and Short radius Elbows , these enable the piping run to move through either 45, 90, and 180 degree angle.

- Equal and Reducing Tees allows connection of a branch at right angles from the main pipe run size.

- Concentric Reducers are used to connect two different size pipes together whilst maintaining good flow characteristics.

- Eccentric Reducers are also used to connect two different pipe sizes together but with one straight side to enable pipe run

to be placed against a wall. - End Caps are used to blank off the end of a pipe run.

45° Elbow

45° Elbow 90° Elbow

90° Elbow 180° Bend

180° Bend Reducers

Reducers

Equal Tee

Equal Tee Cross

Cross Reducing Tee

Reducing Tee End Cap

End Cap

Butt Weld Pipe Fittings are available to ASTM A234WPB and ASTM A403 for Stainless Steels other standards are also available.

Our pipe fittings are usually supplied in accordance with one of the following classes.

WP-B : These pipe fittings are manufactured from Seamless pipe starting material which is pulled or pressed to achieve the desired finished fitting.

WP-W : These pipe fittings are manufactured either from Welded pipe starting material or plate material which is pressed

in to shape and then welded.

WP-WX : These pipe fittings are manufactured either from Welded pipe starting material or plate material which is pressed in to shape and then welded. But then all welds are subject to a 100% radiograph in accordance with ASME section VIII, or other supplied standards.