Manufacturing Process:

Forging or shaping operations may be performed by hammering, pressing, piercing, extruding, upsetting, bending. The forming procedure shall be so applied that it will not produce injurious imperfections in the fittings.

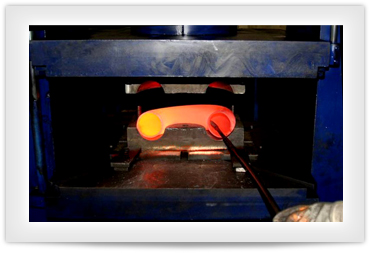

Balaji Industrial Corporation is a manufacturer of quality carbon steel and alloy steel fittings such as Elbow, Return Bend, Tee, Cap and Reducer, Socket Weld Fittings and Flanges by hot process at forming temperature above 620 degree C and below 980 degree C and cooled still in air....

Hot formed or forged carbon steel fittings finished at temperature over 980 degree C shall be normalised and tempered. Hot forged fittings NPS 4 or smaller need not be heat treated. Cold formed carbon steel fittings upon which the final forming operation is completed at temperature below 620degree C shall be normalised or shall be stress relieved at (595 degree C to 690 degree C).

Alloy steel fittings Grades WPII Class I, WP II Class 2 shall be furnished in full annealed, isothermal annealed or normalised and tempered, the tempering temperature for WPII Class I, WPII Class 2 shall not be less than 620 degree C for Grades WP22 Class I and Class 3. The tempering temperature shall not be less than 675 degree C.